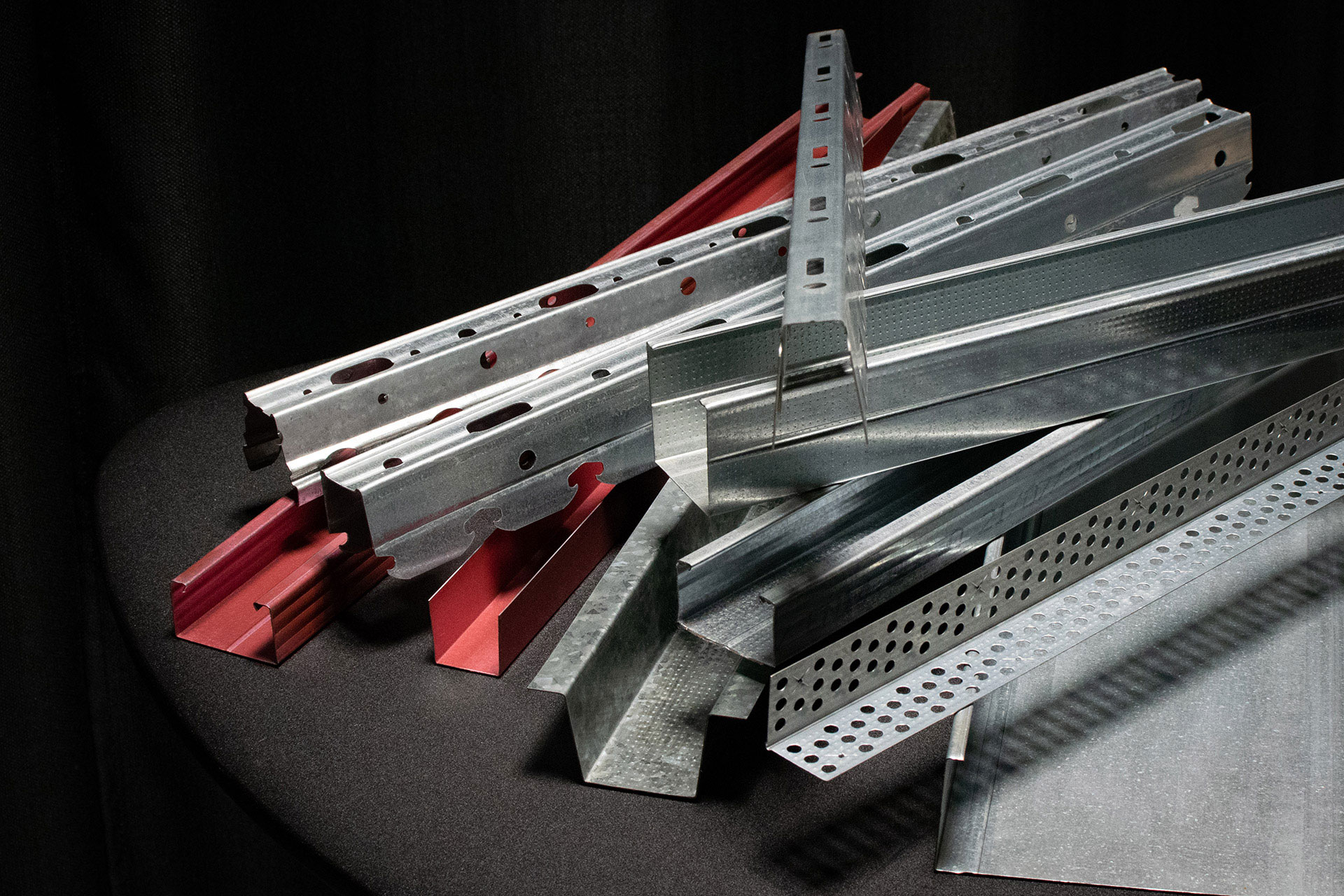

We would like to introduce you two classics of technical interior finishes, which represent a great tradition of our production: Profiles for plasterboard and T-structures for modular false ceilings.

Profiles for plasterboard

The profiles for plasterboard are made of high quality hot-dip galvanised carbon steel type DX51D + Z in accordance with EN 10346.

We also use high-performance raw materials such as:

- Zinc-Aluminium, for greater resistance to corrosion both indoors and outdoors;

- Zinc-Magnesium, for an extraordinary degree of corrosion protection in the most hostile environments.

Both are performing thanks to the healing power of the steel in the cutting and drilling areas of the screws.

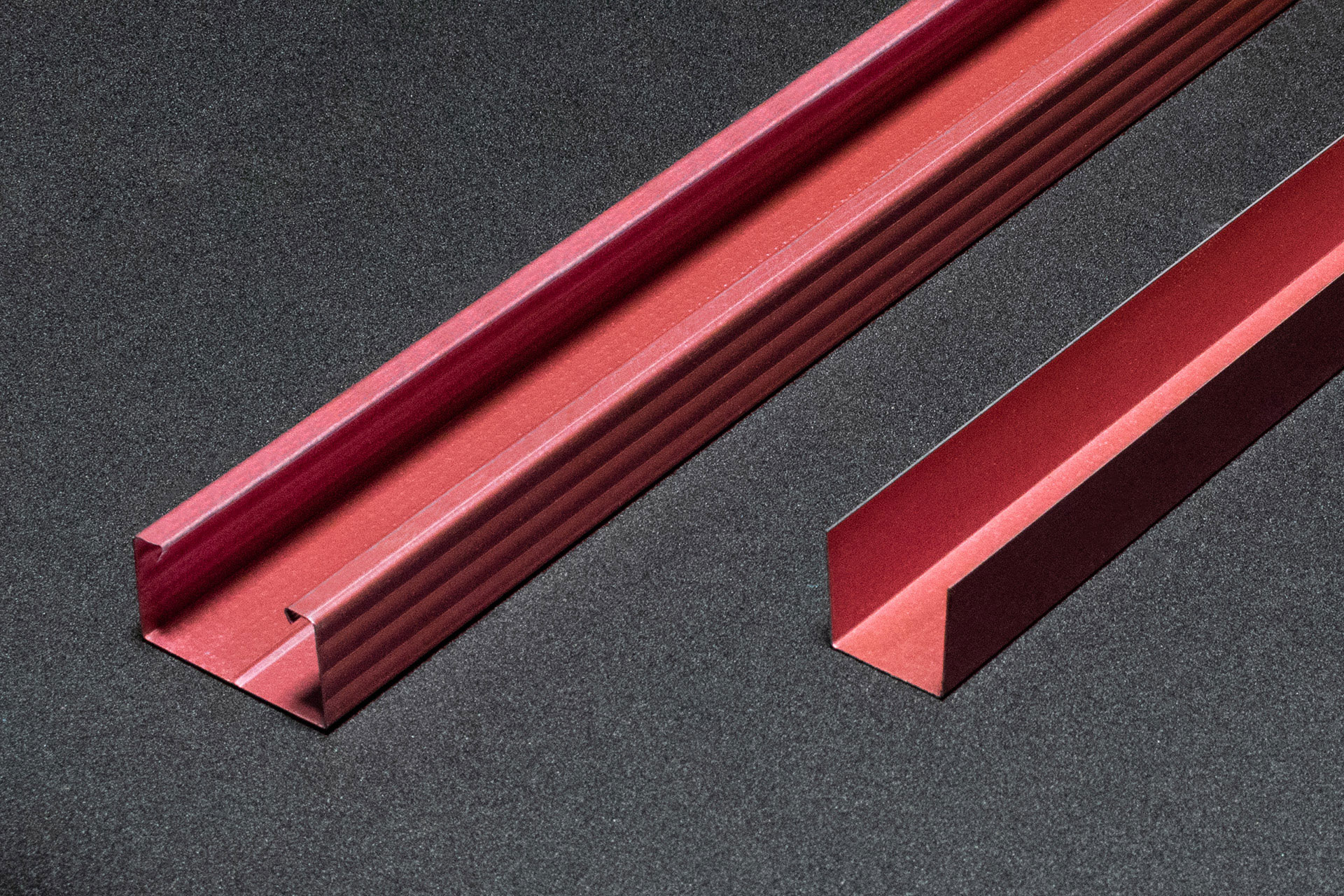

A great innovation is now added to our raw materials: all profiles for plasterboard are made in the exclusive VERTEBRA-ROSSO version type DX51D+Z-AF, which uses hot-dip galvanised steel coated with a thin layer of RED colour, which gives anti-corrosive performance characteristics (oxidation resistance 30% higher), dielectric (avoids the formation of electrostatic charges due to the normal behaviour of the conductive steel), ecological (chrome-free coating) and anti-fingerprint (protective barrier against skin contact and inhalation of oxides that can form on a normal steel improving the habitability of the environments).

The quality of our profiles is attested by the full marking according to Regulation (EU) 305/2011, which establishes harmonized conditions for the commercialization of construction products, and by the CE marking on the product according to the European standard EN14195 (determination of yield strength according to EN10002-1) and EN 13964 (bending strength products for ceiling). All products are accompanied by the DOP (declaration of performance), which indicates the product characteristics required by Annex ZA such as reaction to fire (EN 13501-1), release of hazardous substances, thickness, load, yield strength and durability. The CE mark and the declared information are applied to the product itself.

Thanks to the use of our LEED® mapping obtained in collaboration with TÜV Italia, the products contribute to satisfy the credits of the LEED® certification by analyzing all the aspects for which they contribute to the sustainability of buildings with regard to the content of recycled material as well as the energy contribution they offer.

The range of metal frames for plasterboard includes all the dimensions required by DIN 18180 for both rails and studs, with standard or increased dimensions and thicknesses to meet various application requirements. The supporting carriers, perimeter and complementary profiles and suspension accessories complete the catalogue of proposals dedicated to the dry construction system.

For horizontal partitions the patented G-SEISMIC system (No. 102018000001828), certified and tested according to NTC18 requirements as well as FEMA 461 – “Interim testing protocols for determining the sismic performance characteristic of structural and non-structural components” is perfectly suited to the profiles in order to guarantee in addition to the already proven rigidity an additional anti-seismic support.

Any characteristics?

The rails and studs have widths ranging from 30mm to 150mm. The rails are equipped with holes for ground fixing and the studs with holes for the passage of cables and corrugated.

Snap-on profiles are suitable for all types of suspension. Carriers have mixed drilling to ensure accessibility to different types of suspension.

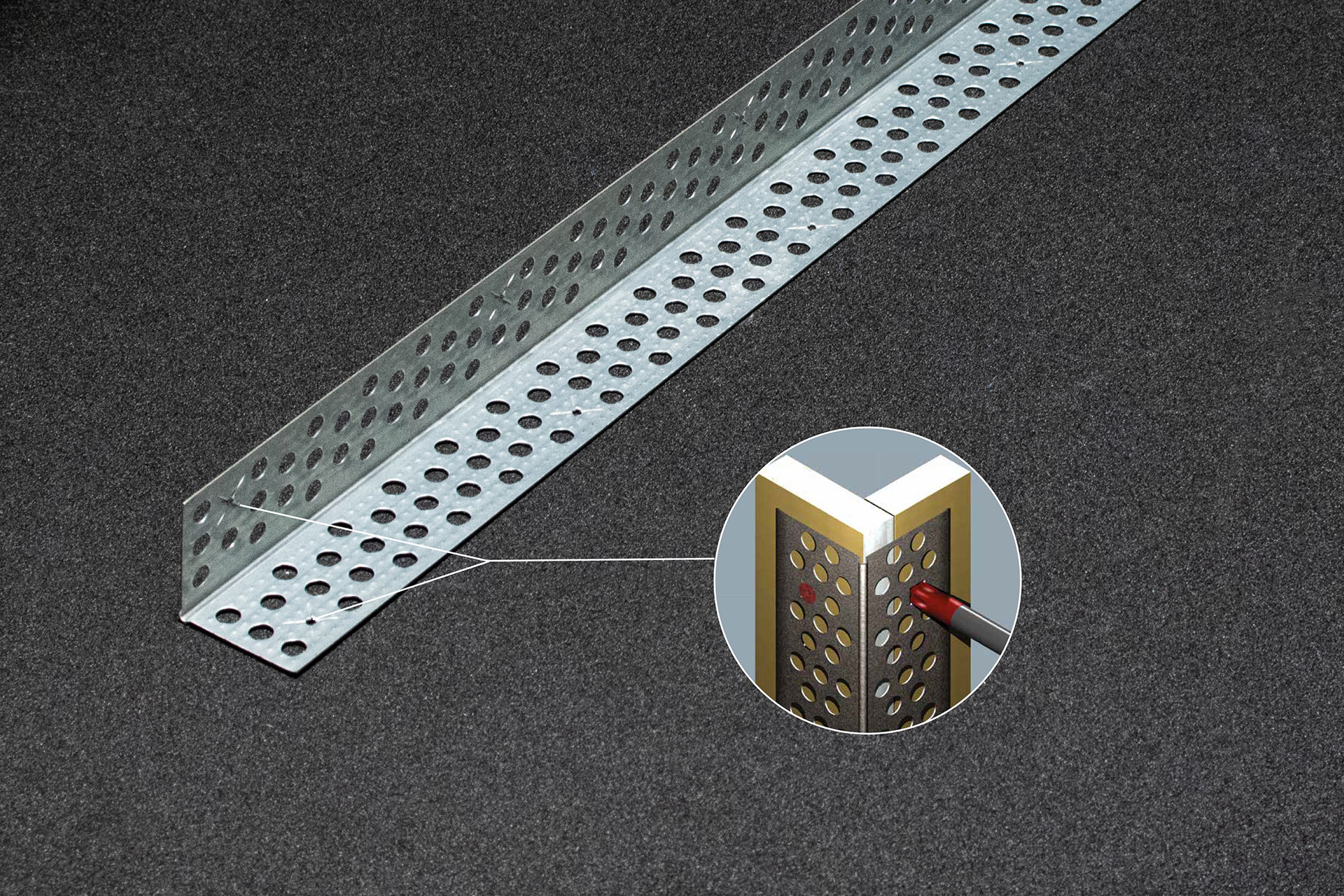

In addition, the patented perforated edge protector PF PLUS allows for quick and economical finishes.

The engravings along the profile sides allow with the simple pressure of a screwdriver or a metal tip to directly crimp the coated plasterboard, without the need to use screws, with the advantage, in addition to the quick fixing, of simplifying and reducing the grouting and finishing of the entire edging.

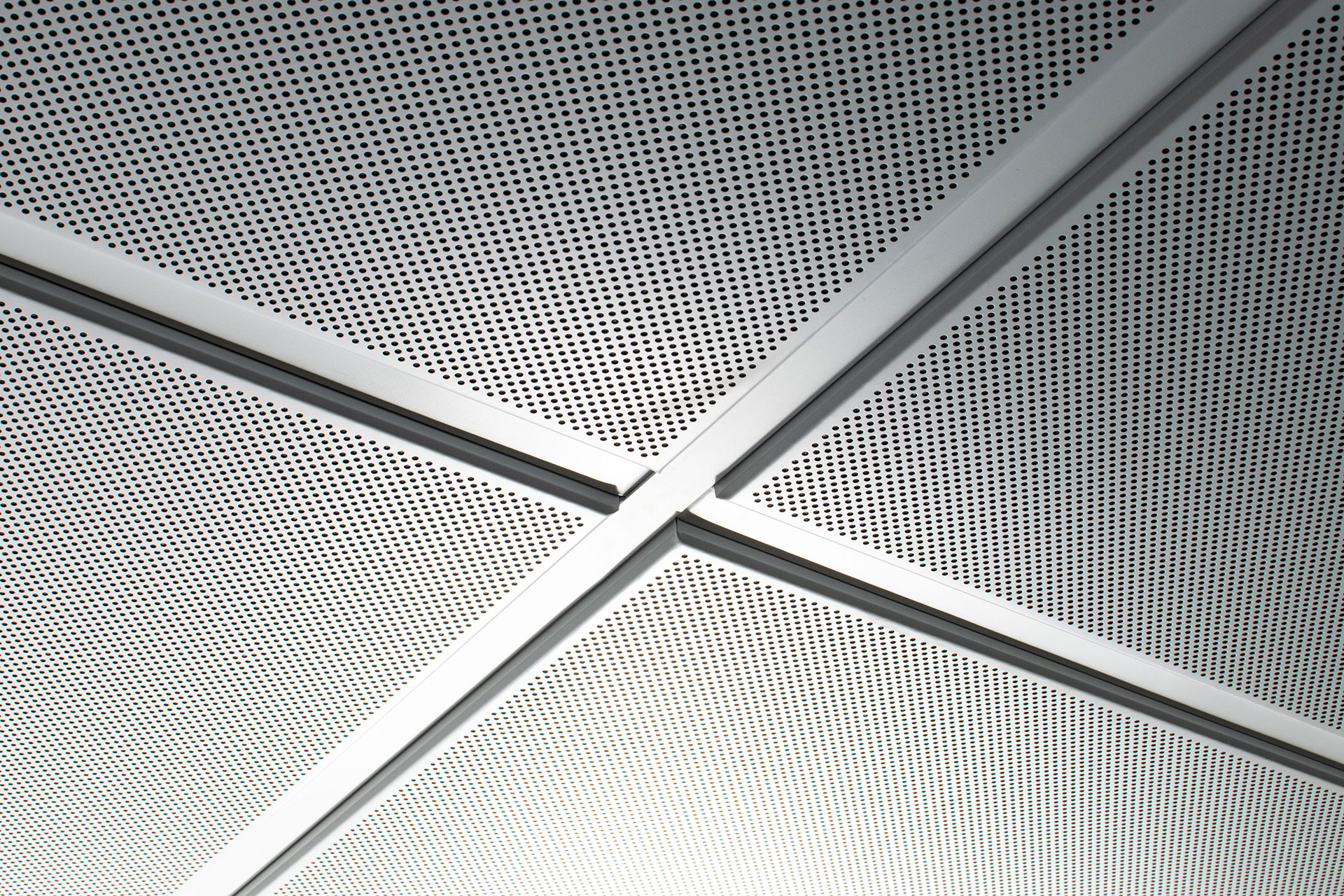

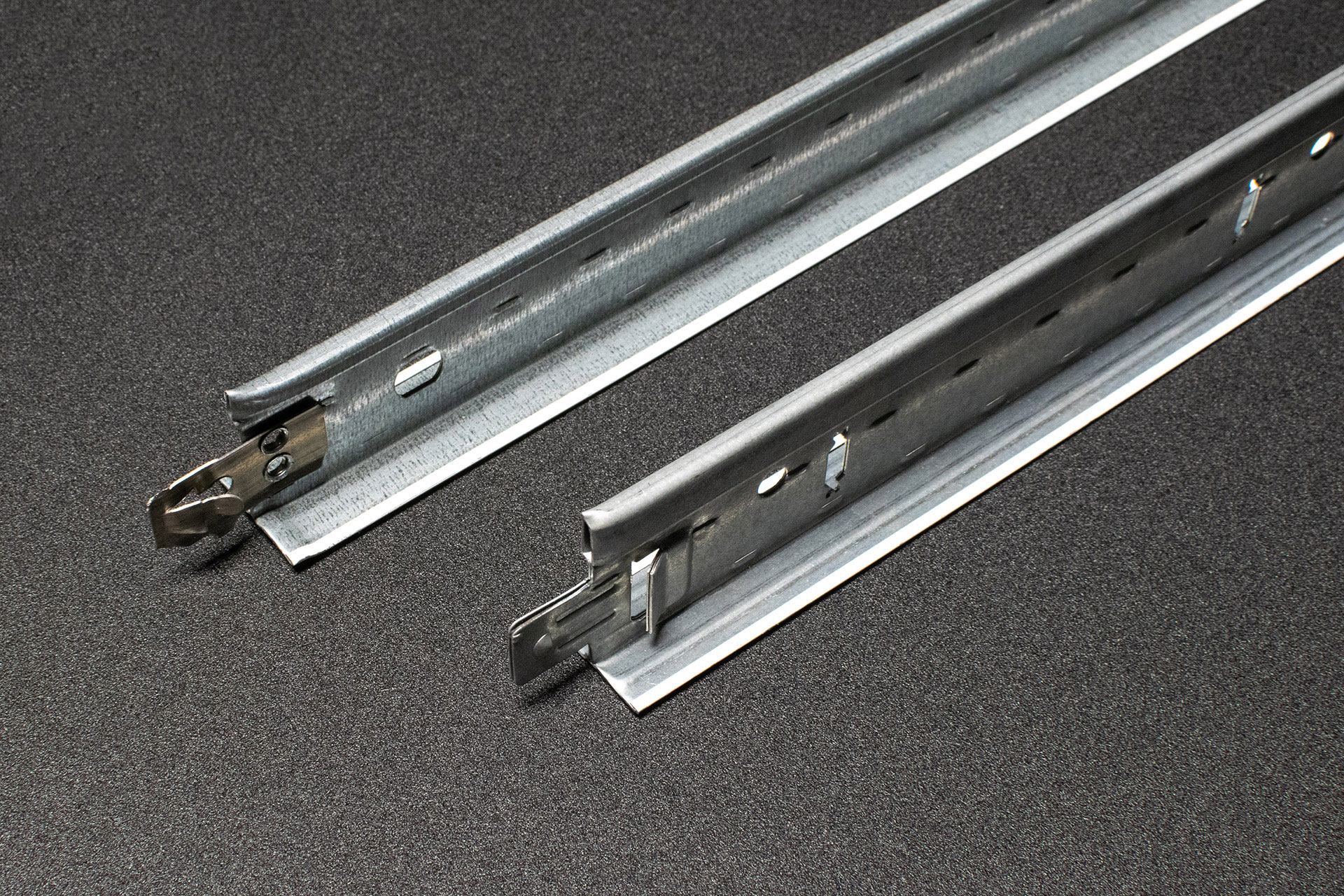

T-structure

T-structures for modular ceilings are still the most popular product in our range today. Over the years we have developed several innovative, earthquake-proof and at the same time removable hooking systems: ” Freccia” (patent No. 102009901729027) for T24 and T15 is the reference point for installers. With “Freccia” it is possible to realize multiple modules based both on metric (mm) and imperial (inch) system. The strong point is the disassembly and reassembly of the profile without any hook deterioration.

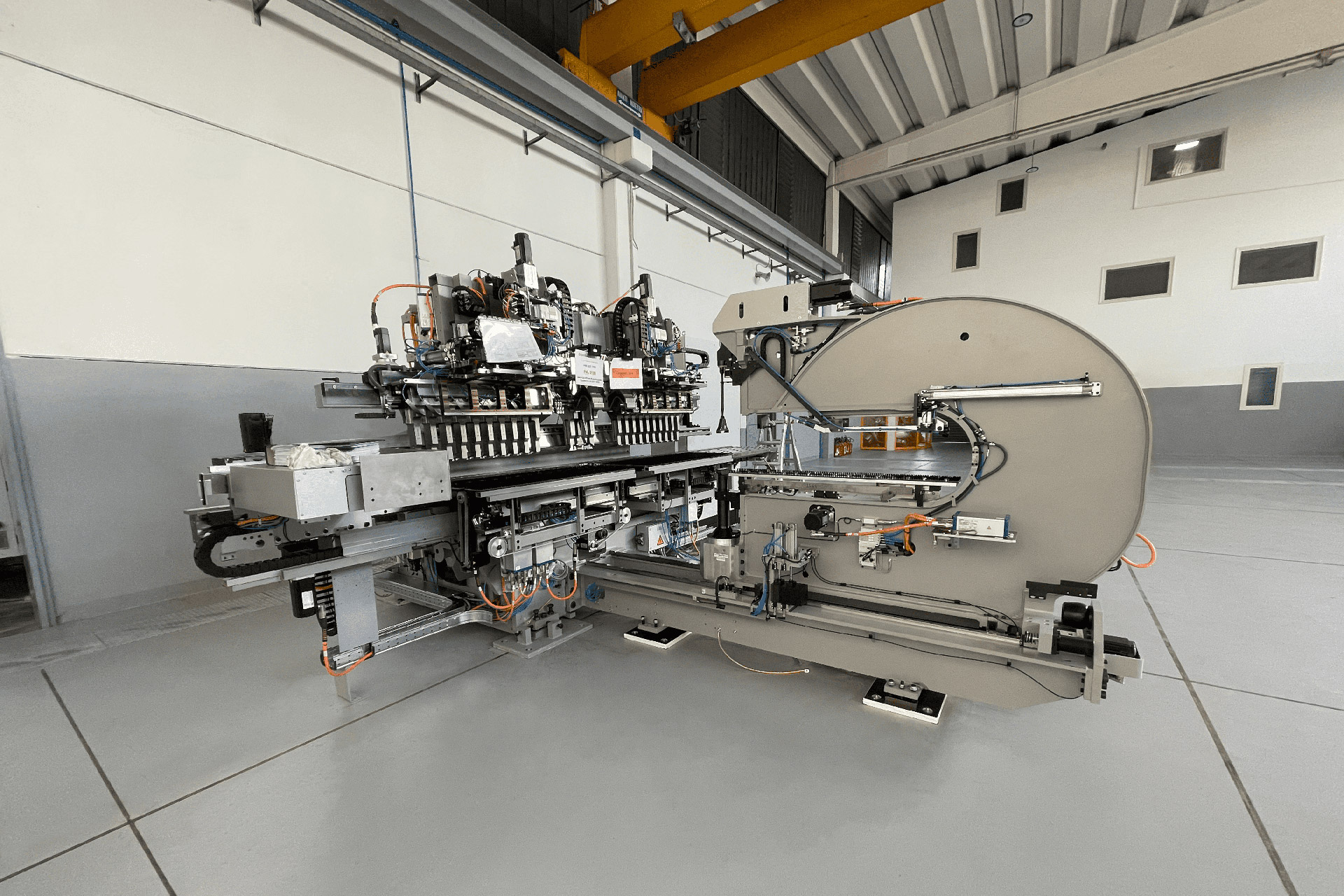

For the production of T-structure, hot-dip galvanised steel in accordance with EN 10346 is used in the standard version; in the case of use of other types of steel, the substructures are produced with materials that comply with EN 10152, EN 10169-1. The tolerances and thicknesses are checked in accordance with the requirements of EN 10143 (for EN 10346 and EN 10169) and EN 10131 (for EN 10152).

The ” Freccia” profile is also available in the following versions:

- with antibacterial treatment for which the microbial load is reduced by more than 95% after 24h according to ISO 22196;

- with anticorrosive treatment according to the degree of corrosion required, which with special treatments prevents galvanic currents and corrosion of the structure;

- in aluminium alloy suitable for both diagnostic (non-magnetic environments) and public areas where a higher degree of protection is required (e.g. swimming pools and thermal areas, with concentration of humidity and chlorine).

The supporting structure also has an expansion joint designed to correctly absorb the elongation of the structure due to thermal expansion or other phenomena such as earthquakes for example.

The quality of our profiles is attested by the full marking according to Regulation (EU) 305/2011, which establishes harmonised conditions for the commercialization of construction products, and by the CE marking on the product according to the European standard EN 13964 (mechanical resistance to bending of products for ceiling). All products are accompanied by the DOP (declaration of performance), which indicates the product characteristics required by Annex ZA such as reaction to fire (EN 13501-1), release of hazardous substances, thickness, load, yield strength durability and flexural strength class. The CE marking and the declared information are applied to the product itself. The product has the fire resistance certificate REI120 (13501-2) in combination with rockwool or fibre wool panels having equivalent characteristics – Clay cement ceiling.

Thanks to the use of our LEED® mapping obtained in collaboration with TÜV Italia, the products contribute to meet the LEED® certification credits by analysing all the aspects for which they contribute to the sustainability of buildings with regard to the recycled material content and the energy contribution they offer.

The patented G-SEISMIC system (No. 102018000001828), certified and tested according to the requirements of NTC18 as well as FEMA 461 – “Interim testing protocols for determining the sismic performance characteristic of structural and non-structural components” is perfectly adapted to the T-structure in order to guarantee, in addition to the already proven rigidity, an additional anti-seismic support.